Electrical discharge machining

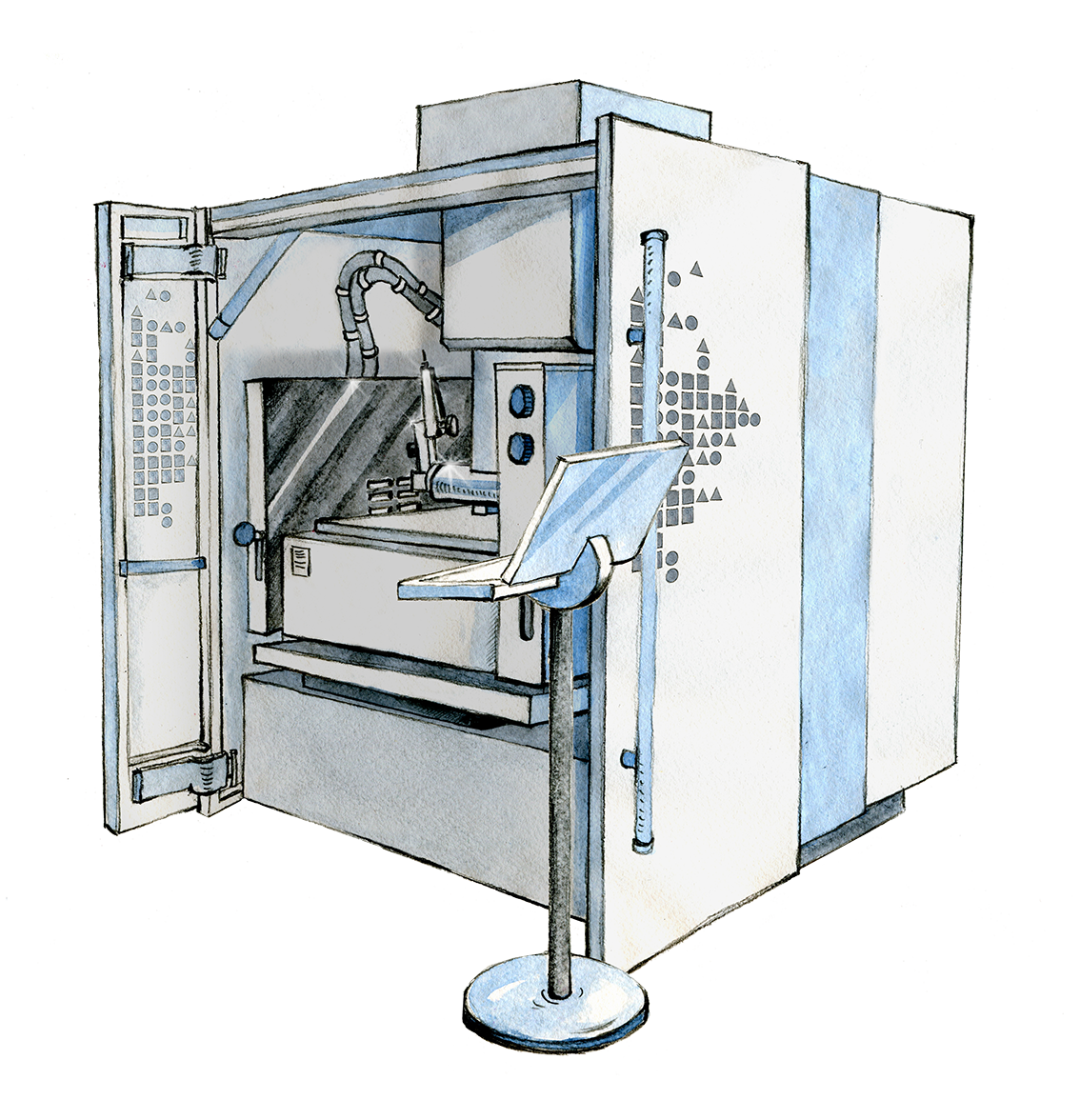

Wire-Cut EDM

With nearly 20 years of experience in working with wire-cut EDM, our company has the dedication, knowledge

and capability to fulfill even the most challenging customers’ requirements including independent 4-axis taper cutting, partly necessary for cogwheels, dies and drawing punches, which belongs to the division’s normal workday..

Masses: up to 50kg

Dimensions: max. 350mm x 250mm x 150mm

Materials: all steels (tool steels, CrNi-steels, hot-work steels,…) cast irons, non-ferrous steels, light metals, …

Control Unit(s): Agie

(CAD/CAM): mecanic and Solid Works/Solid CAM

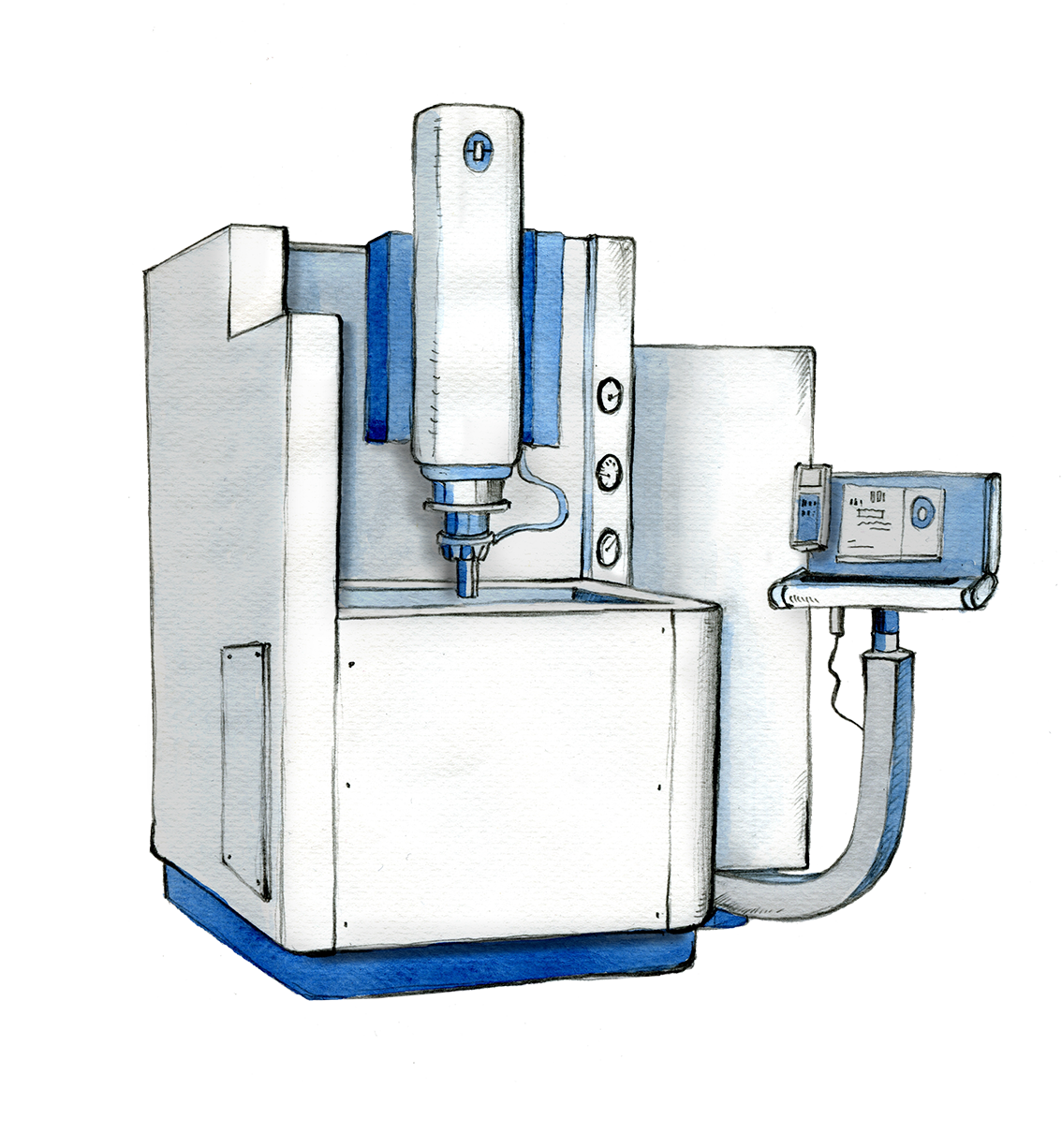

Die sinking

The customer can benefit and draw from our experience and expertise in processing blanking and bending tools, injection moulds for plastic and the single components and batch production for the engineering, automotive, electronics, semiconductor, energy and medicine industry..

With the die sinking method for example, it is also possible to subsequently work in a thread into an already hardened work piece!

Masses: up to 50kg

Dimensions: max. 600mm x 400mm x 300mm

Materials: all steels (tool steels, CrNi-steels, hot-work steels, …), cast iron, non-ferrous metals, light metals, carbides, ...

Control Unit(s): Agie

(CAD/CAM): Solid Works/Solid CAM