Quality Management

Quality assurance in machining is of paramount importance to ensure that manufactured parts meet customer requirements and technical production drawings.

Your satisfaction is our priority:

Production Monitoring

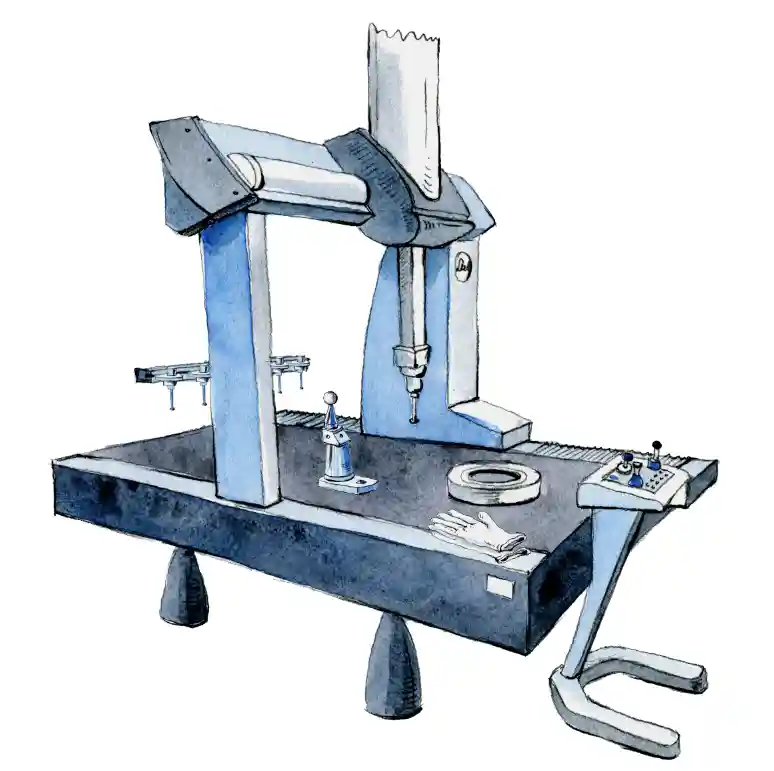

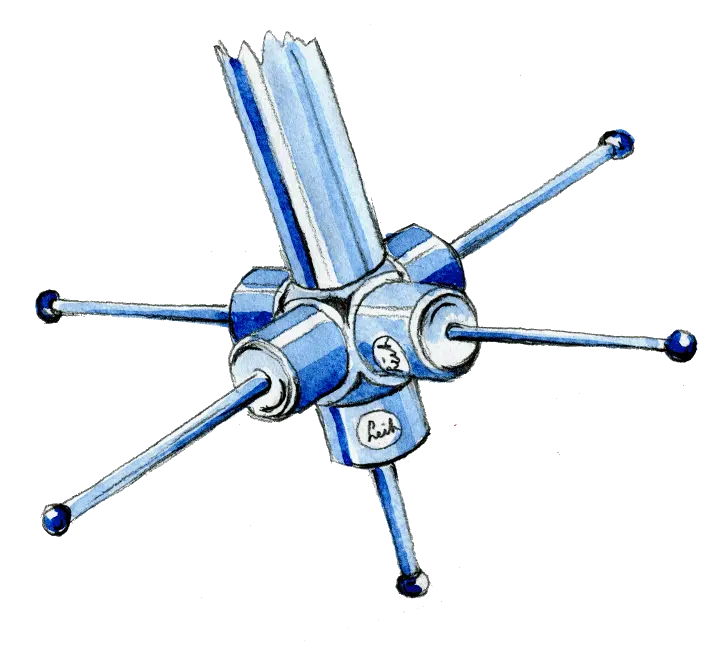

Thanks to production-accompanying inspections, we guarantee the highest quality and precision. Leading precision measuring devices such as measuring prisms, roughness measuring devices, measuring towers, and other measuring machines, are used for this purpose.

Our highly sensitive temperature monitoring system ensures optimal climate control to prevent dimensional variations. Technicians continuously monitor each workpiece to ensure manufacturing tolerances according to customer specifications.

Regular replacement and calibration of measuring devices ensure our technological advantage in the field of quality control.

Our in-house PR system (problem reporting system) records and registers deviations, ensuring that customers receive only the highest product quality.

Final Inspection

We have climate-controlled measurement rooms equipped with a range of premium measuring instruments, including 3D measuring machines (CMM accuracy: 0.9 µm + L/350). Sophisticated software ensures precise measurement data evaluation, and ongoing development of our testing processes allows for early error detection and subsequent manufacturing optimization.

With this holistic approach, we are well-equipped to deliver high-quality and highly precise components and assemblies that meet our customers' requirements.