Mechanical Manufacturing

Thanks to our modern machinery and experienced technicians, we specialize in precision machining, electrical discharge machining, and the heat treatment of metals and plastics.

Continuous training and investments in our manufacturing capabilities enable us to deliver the highest precision and quality in the fields of metalworking, erosion machining, and steel heat treatment. This sets us apart from traditional contract manufacturers in the machining industry.

Metals handled through machining and erosion processes are data-recorded at each step and subjected to rigorous quality control. This ensures the delivery of components that meet your requirements in every respect.

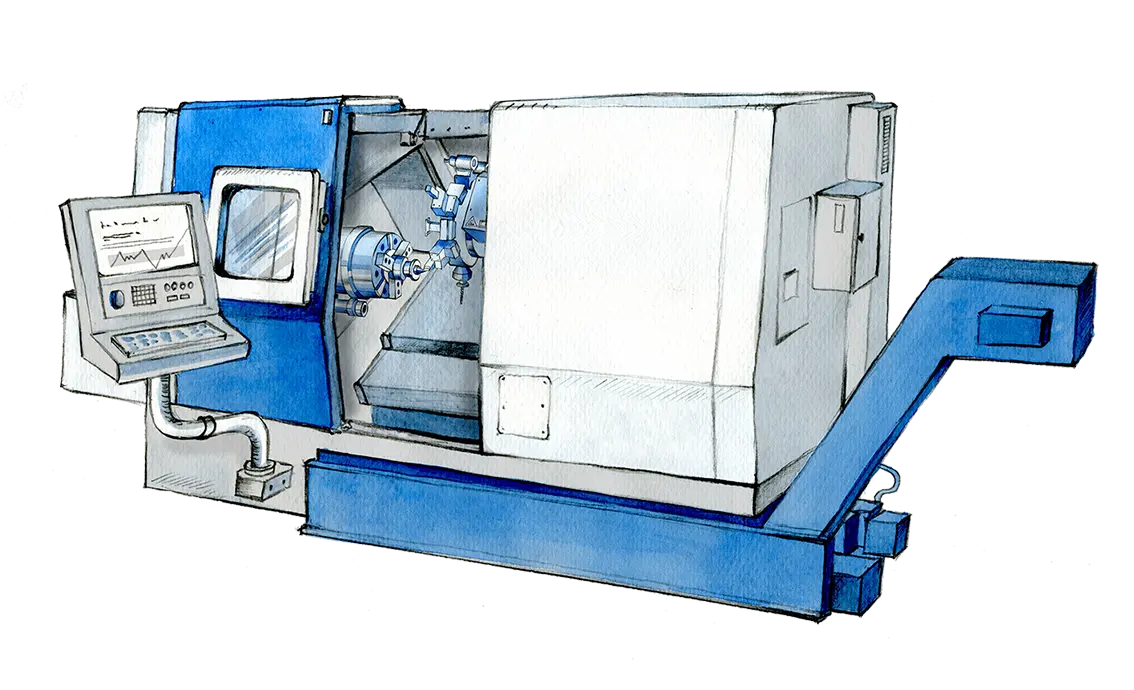

Turning

In our state-of-the-art CNC turning department, we have the capability to fulfill a majority of customer requests ranging from diameters of >Ø 0,5 mm to <Ø 900 mm. Our expertise in custom precision turned parts allows us to produce tailor-made precision turned components. You benefit primarily from our strengths in individual part and CNC series production. Each component is digitally recorded with 100% digital manufacturing documentation in accordance with our high-quality standards, setting us apart from traditional contract manufacturing.

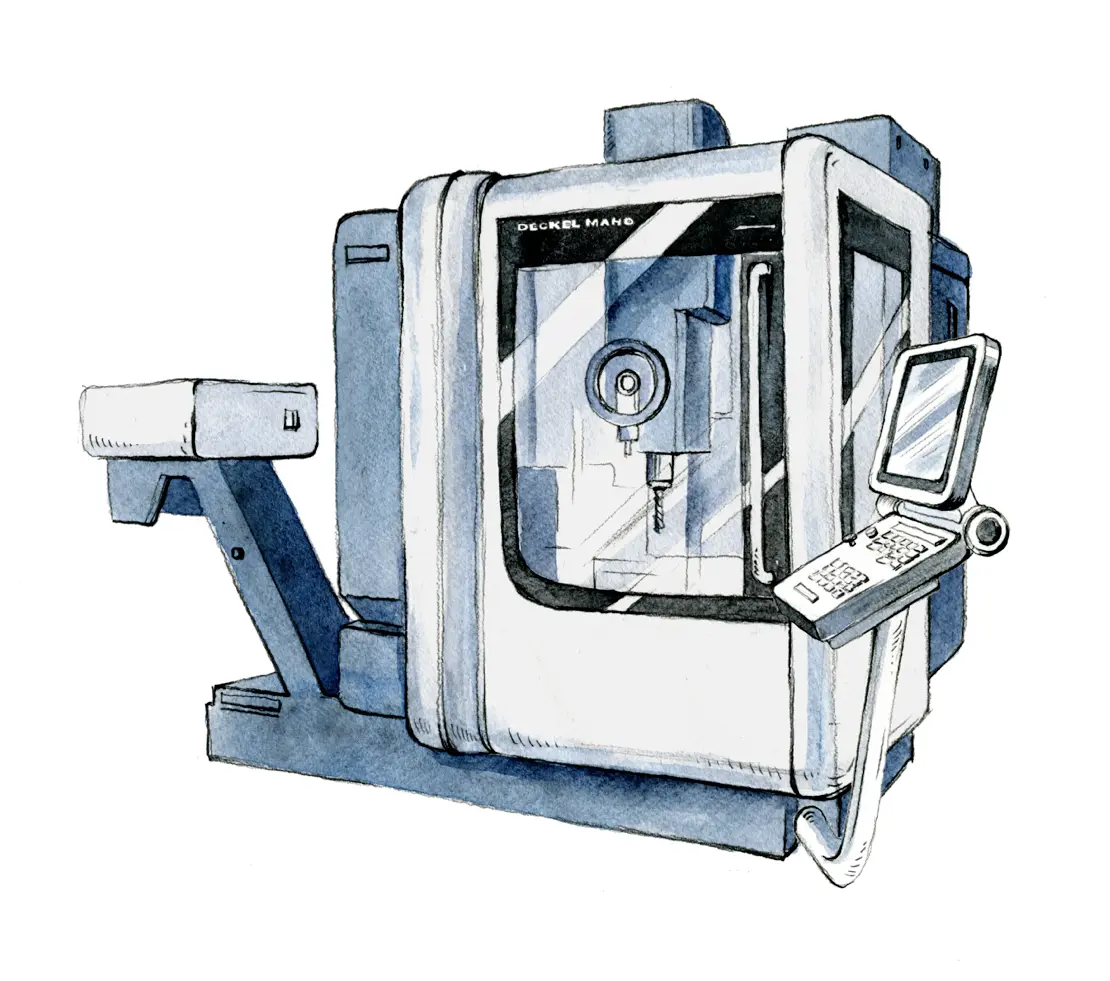

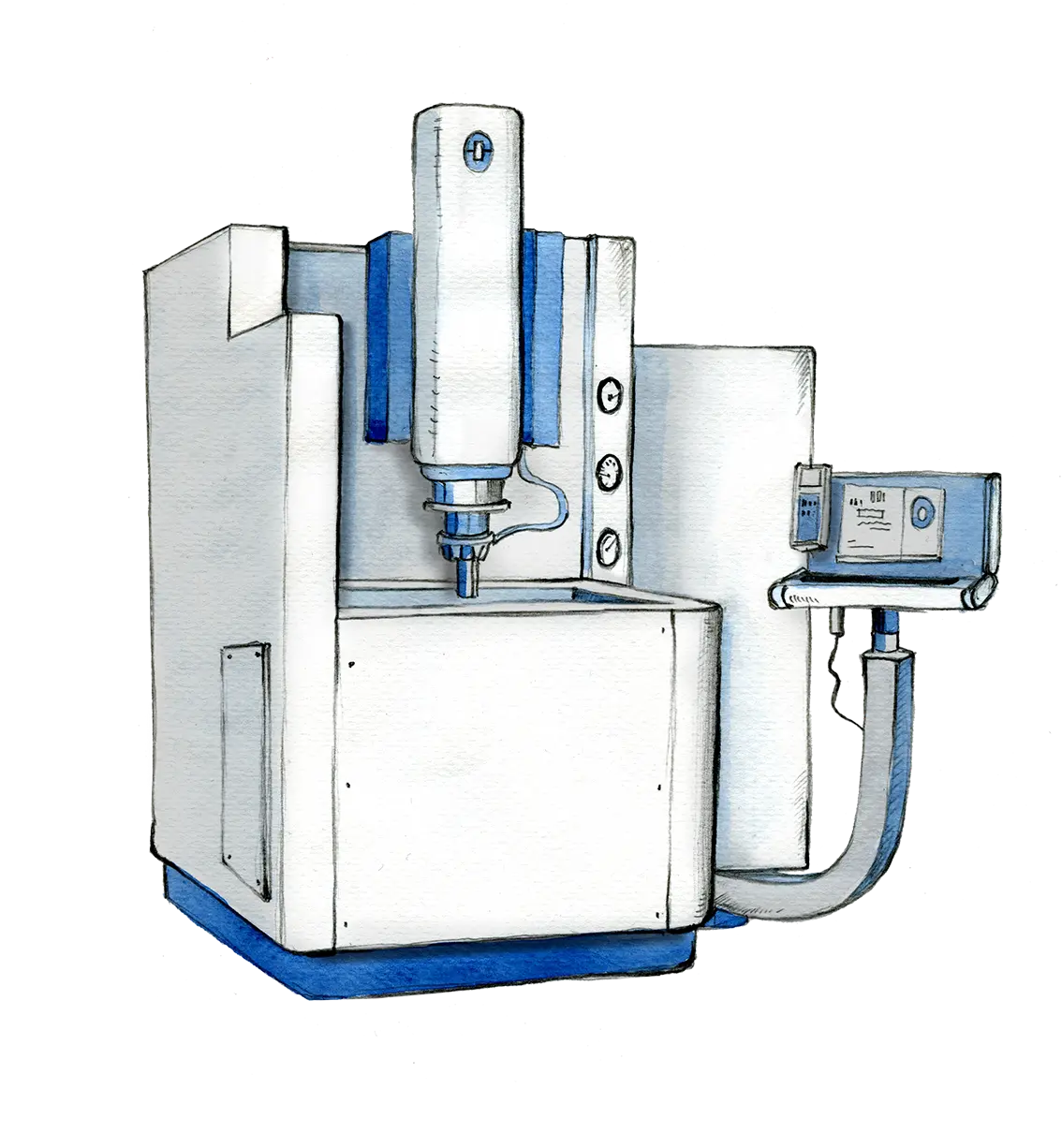

Milling

Our comprehensive machinery enables us to produce complex single-milled parts and serial parts. Our machine spectrum ranges from conventional milling machines and 3-axis CNC universal milling machines to 5-axis machining centers for optimal performance and complete machining in a single setup. We mill metal based on drawings and achieve the highest precision in CNC milling. Through the combination of turning and milling, we can manufacture components of various levels of complexity.

Grinding

Surface Grinding

High-precision surface grinding machines and CNC grinding allow us to manufacture parts within very tight tolerance ranges and complete the production process after turning or milling. Surface grinding can be used to work on a variety of steels and hard metals. Profile grinding, deep grinding, surface grinding, and plunge grinding are some of the additional machining technologies within our manufacturing offerings.

Cylindrical Grinding

With our high-precision cylindrical grinding machines, we offer not only traditional external, internal, contour, and thread grinding but also the precision of modern CNC control to meet your specific requirements in CNC cylindrical grinding. This provides you with diverse manufacturing options and ensures outstanding surface quality. With our expanded range of services, we offer you a comprehensive package in metal processing.

Erosion

Wire Erosion

Wire erosion is a shaping manufacturing process.

Small geometric contours, regular surfaces in various combinations, cylindrical and conical shaping, with variations of angles on both large and small, hardened, and non-hardened workpieces - all of this can be achieved with precision using wire erosion and the necessary expertise in this field.

In Austria, we have decades of experience in these technologies and the erosion of metals in general. This expertise is essential to meet your specific product requirements and our manufacturing goals. That's our aim.

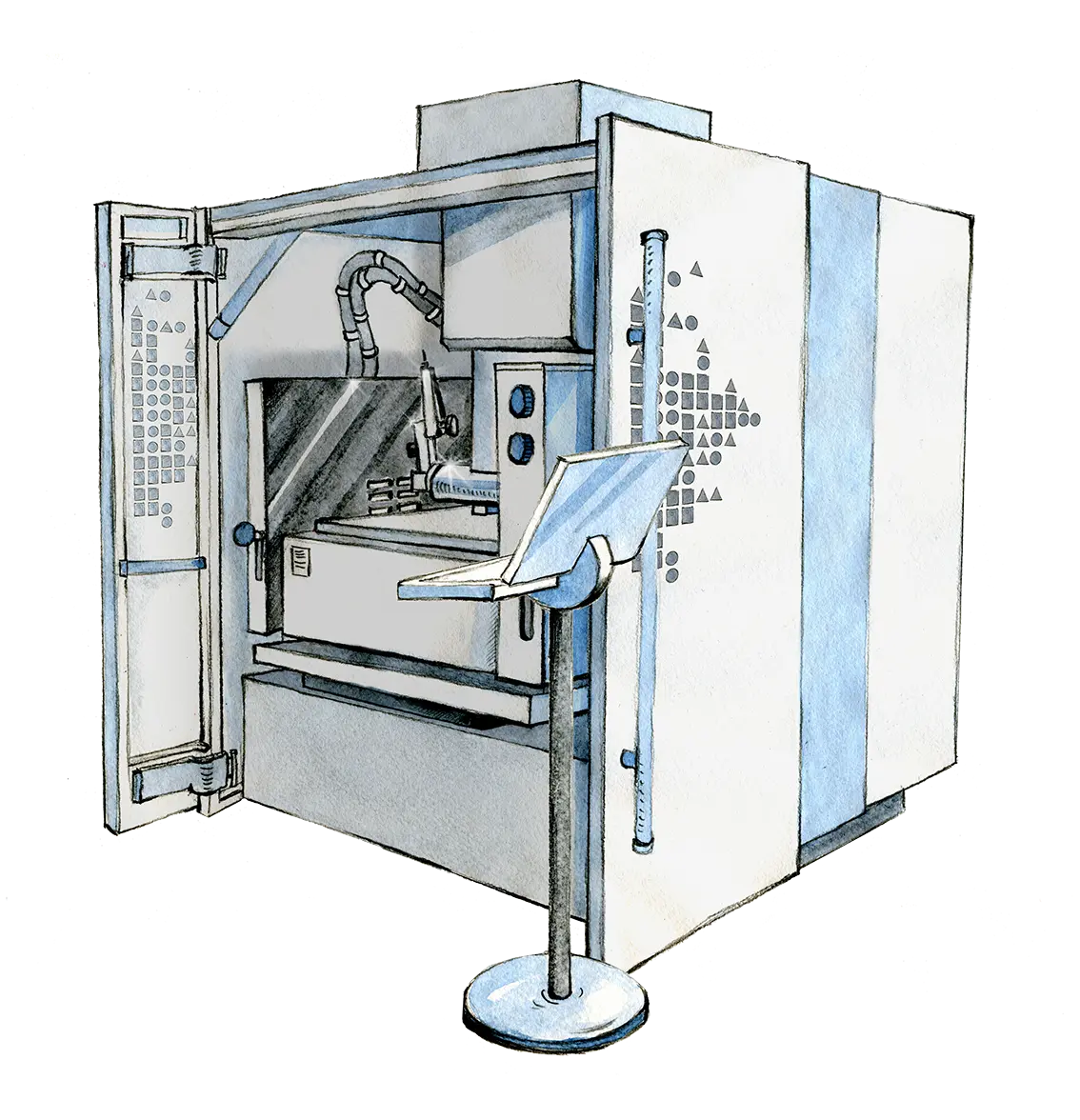

Die-Sinking EDM

The difference between die-sinking EDM and wire EDM lies in the fact that die-sinking EDM uses a pre-formed electrode to erode contours in a workpiece, whereas wire EDM uses a continuously fed wire as an electrode to create precise cuts in the material.

Die-sinking EDM, as a sub-discipline of spark erosion, also known as EDM (electrical discharge machining), complements our manufacturing spectrum and enables us to produce highly complex components.

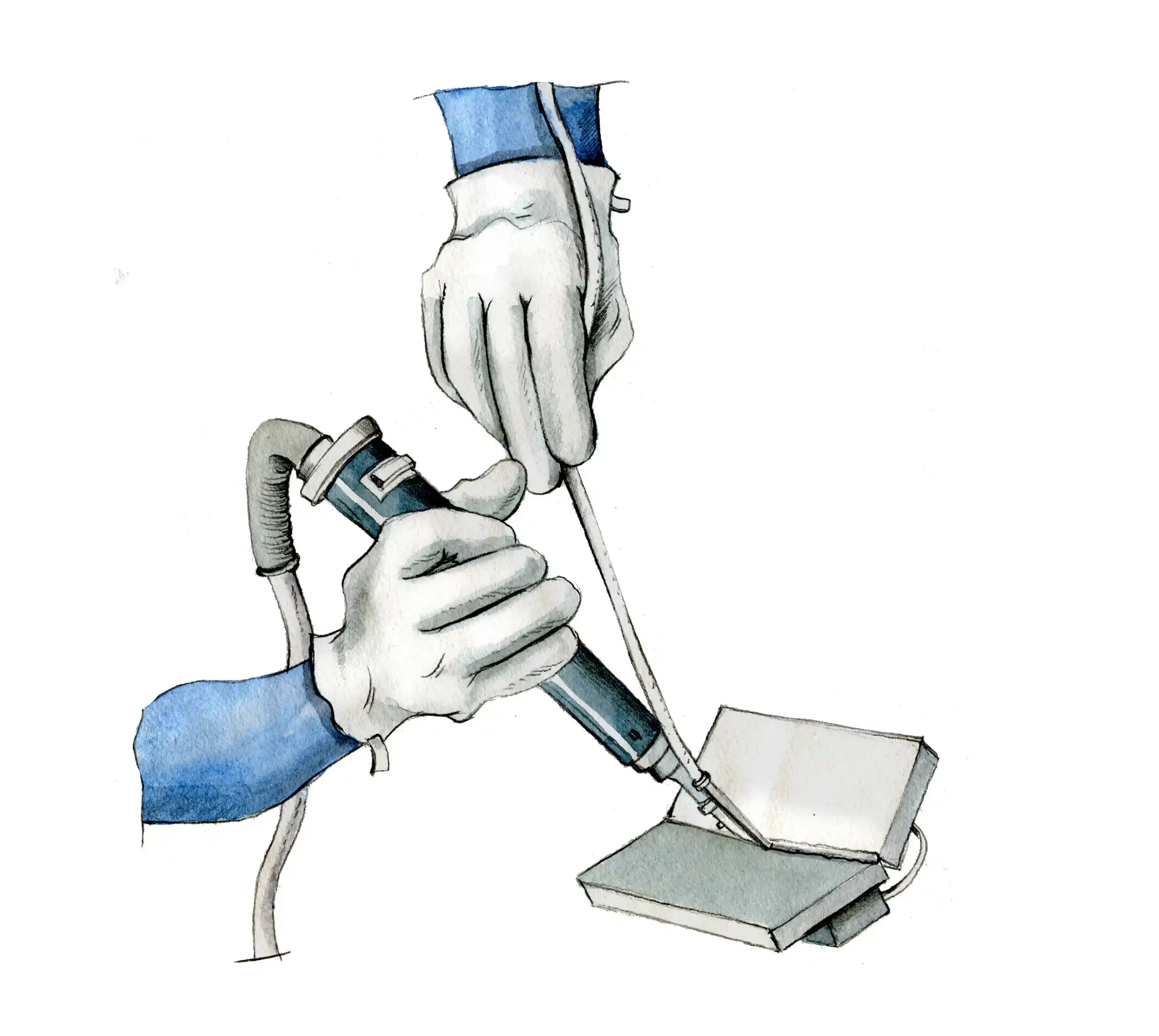

Plastic Welding

In our facility, we utilize the method of hot air welding, or heat element welding, for plastic welding. In this process, the surface of the plastic is melted and then fused together. This plastic welding technique is particularly well-suited for the materials we offer in our product range.

The advantages of this process lie in the separate heating and joining of the parts, the ability to create continuous seal welds, and the capability to weld different plastics together. This is not the case with ultrasonic plastic welding, for example, as it can only process certain materials.

Our technicians ensure that the processing is carried out precisely and efficiently to guarantee the best possible quality and performance.

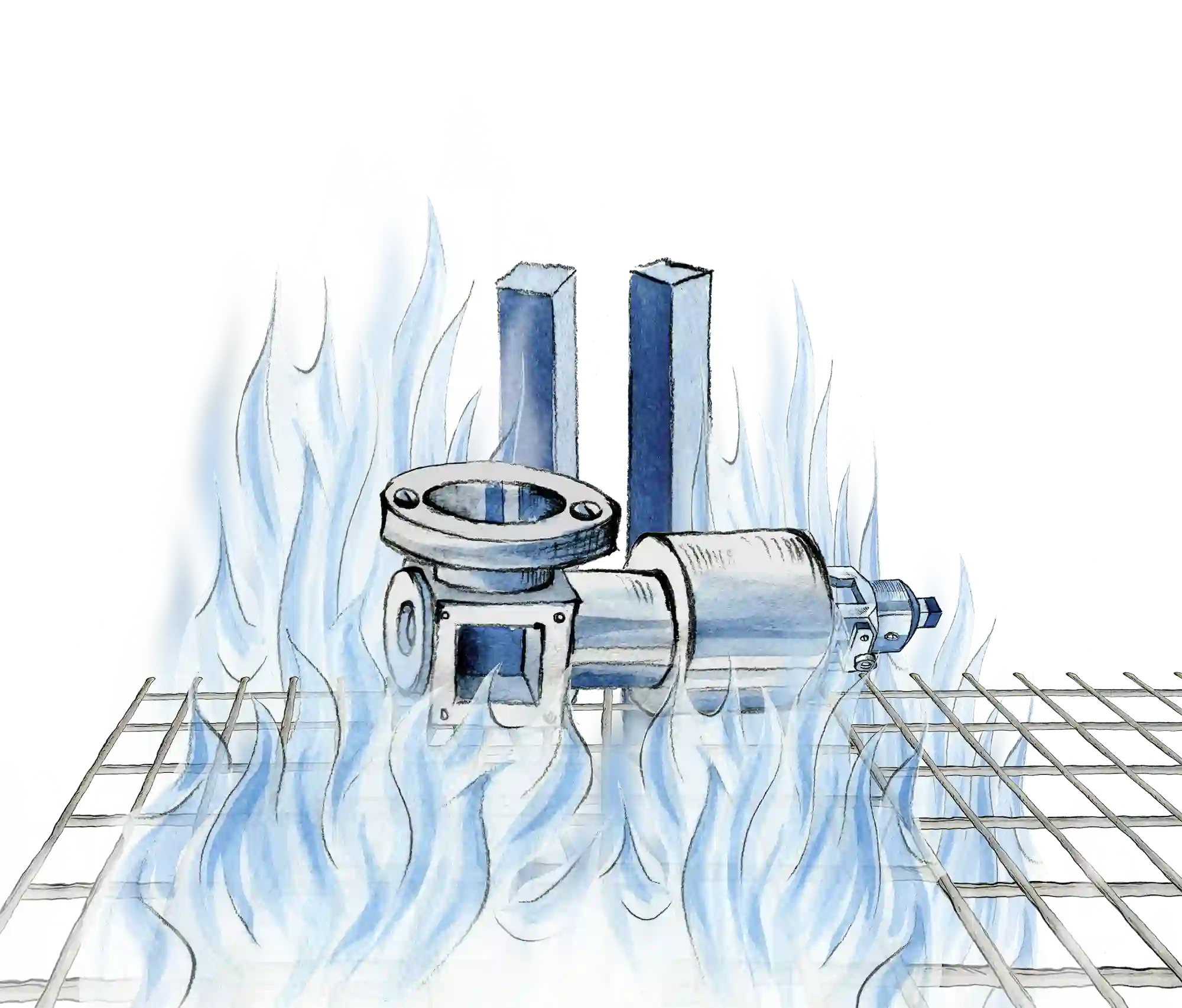

Hardening and Annealing

The manufacturing specialists at our company location are also capable of hardening steel and subsequently annealing it. Annealing changes the mechanical properties of the steel, increasing the component's durability. Case hardening and surface hardening of smaller components are also within our treatment capabilities.

For larger components or specialized treatments (such as protective gas hardening and induction hardening), we rely on our long-standing network of partners who specialize in these areas.

This allows us to meet all specific requirements and process components of various sizes.

Tempering

Tempering plastic refers to the controlled heating and cooling of plastic components. This process is used to reduce internal stresses that can occur during manufacturing. The result is often a more durable material. The benefits of plastic tempering include increased resistance and reduced warping. Additionally, the curing of the plastic can be improved.

In our manufacturing, we have also specialized in tempering plastics before and between processing steps, offering comprehensive solutions in this field.