Processing of High-Performance Polymers

We specialize in machining and manufacturing high-performance plastic parts, combining our in-depth expertise with the latest technologies. Special turning, milling, and welding processes enable us to process various high-performance plastics.

This guarantees you:

Customized Solutions:

Thanks to our extensive machinery, we are able to meet a wide range of requirements.

Quality through Selection:

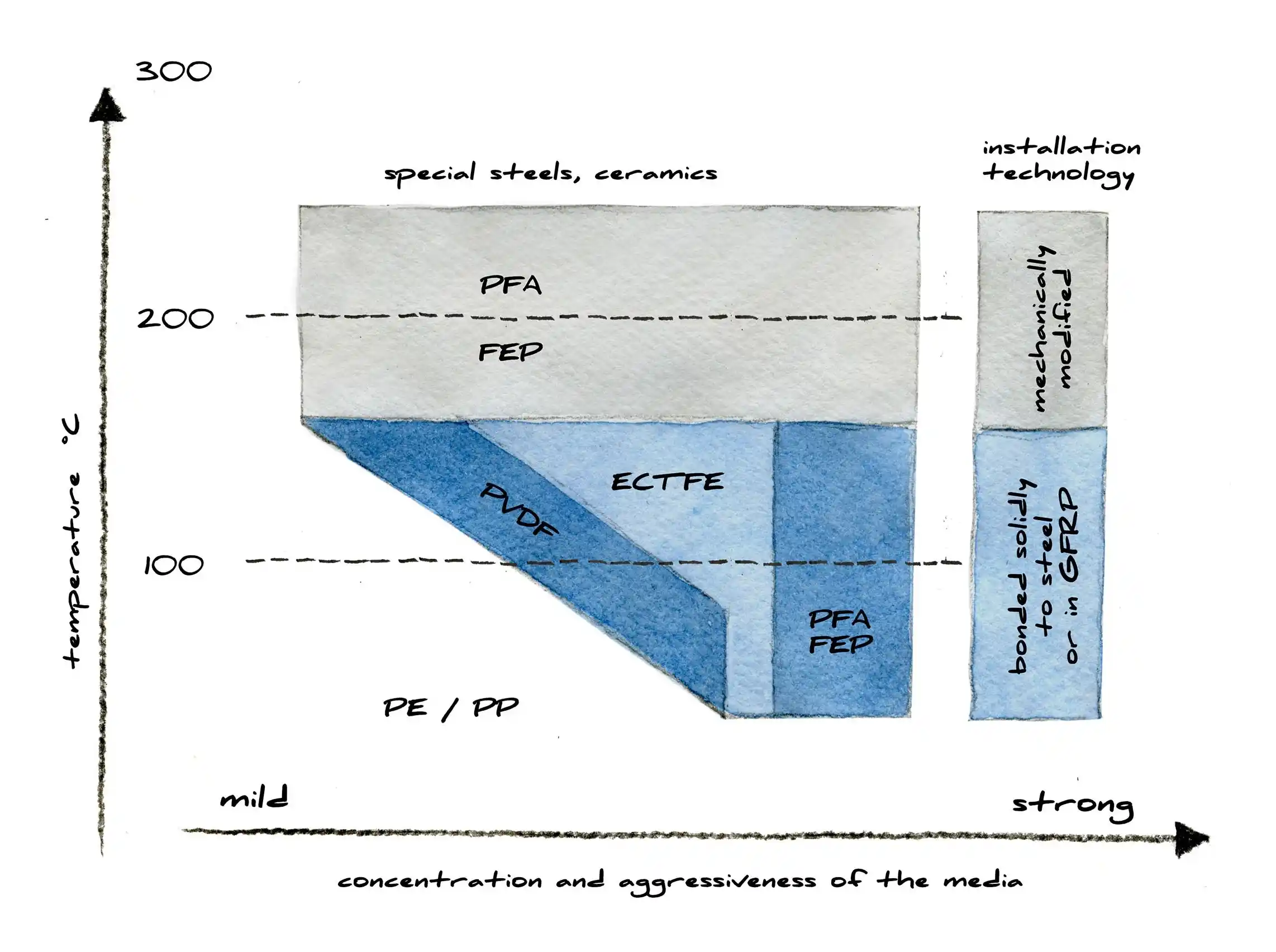

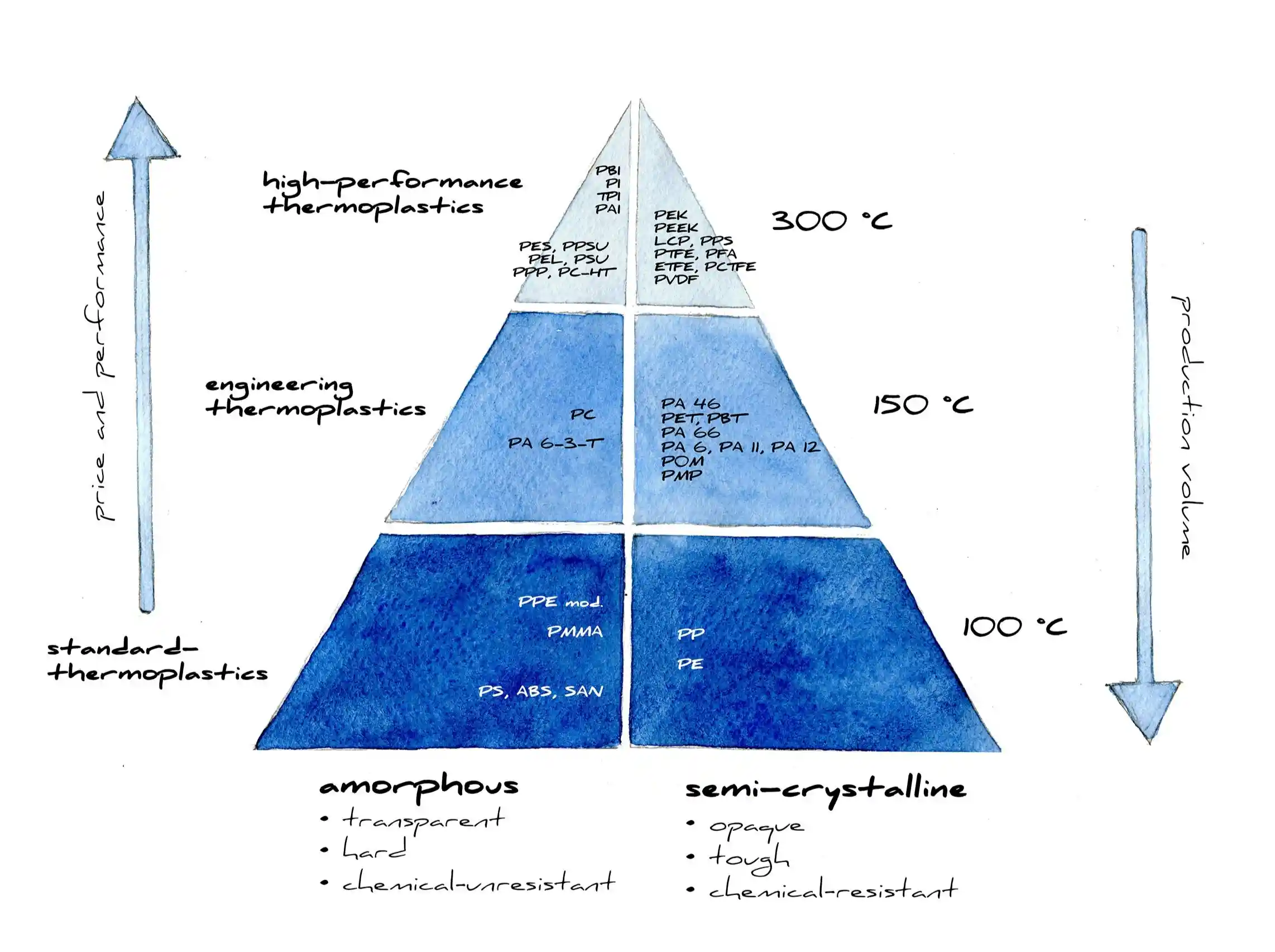

Our high-temperature plastics, such as the temperature-resistant VESPEL® polyimide, acid-resistant polyvinylidene fluoride (PVDF), durable polychlorotrifluoroethylene (PCTFE), or low-friction polyoxymethylene (POM), are chosen specifically for your application.

Companies from the following industries are already benefiting from our solutions:

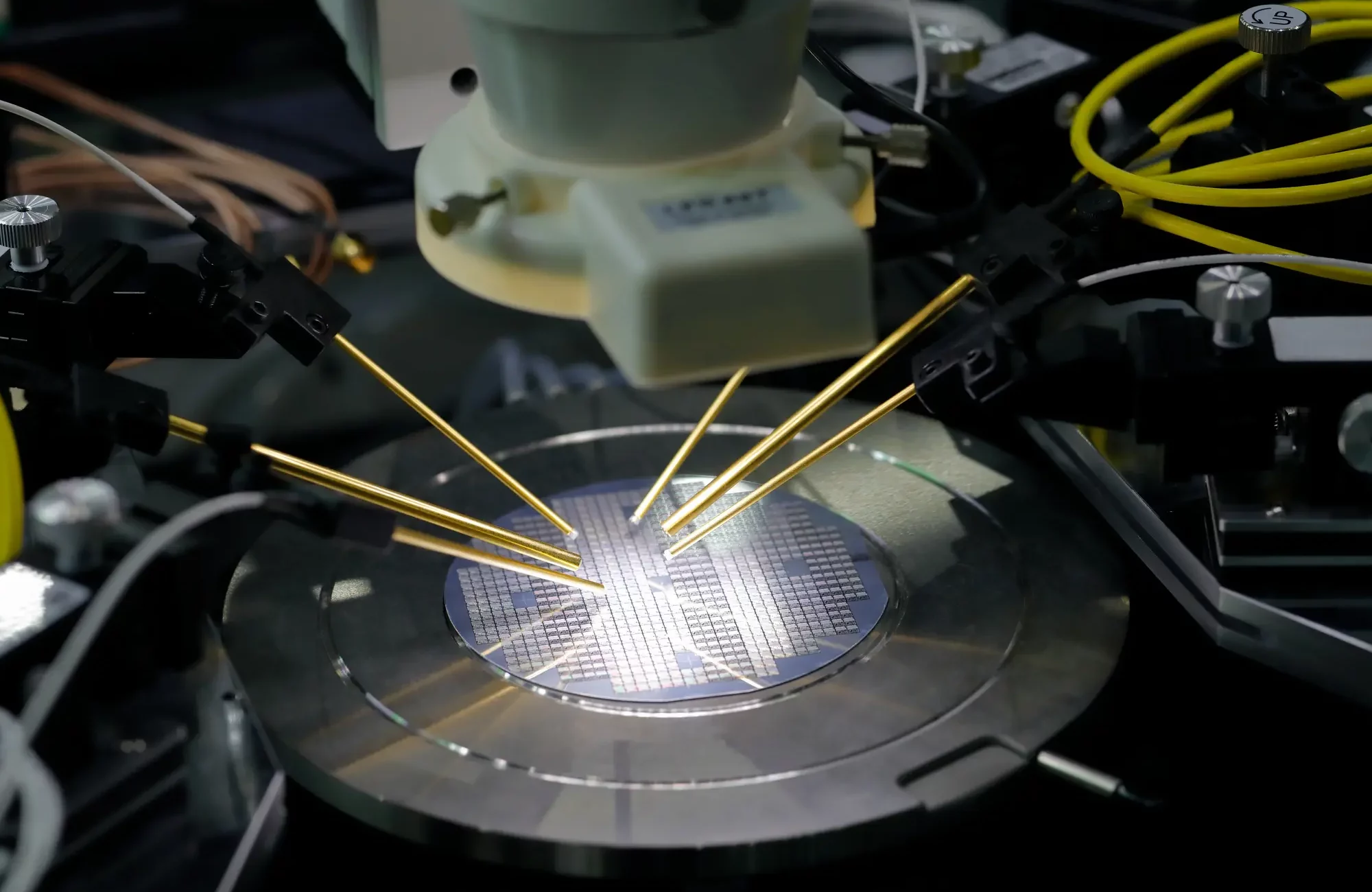

Semiconductor equipment:

The use of high-performance plastics in robots and manipulators is essential in wafer manufacturing. They minimize particle generation, thereby preventing contamination. Additionally, they are chemically resistant, making them ideal for use with aggressive chemicals in semiconductor manufacturing. Depending on requirements such as chemical resistance, electrical insulation, and cleanroom compatibility, engineering plastics are crucial for the quality and efficiency of our manufacturing processes.

Medical engineering:

Manufacturing of components for medical devices that need to be sterile, biocompatible, and compliant with ISO 13485 standards.

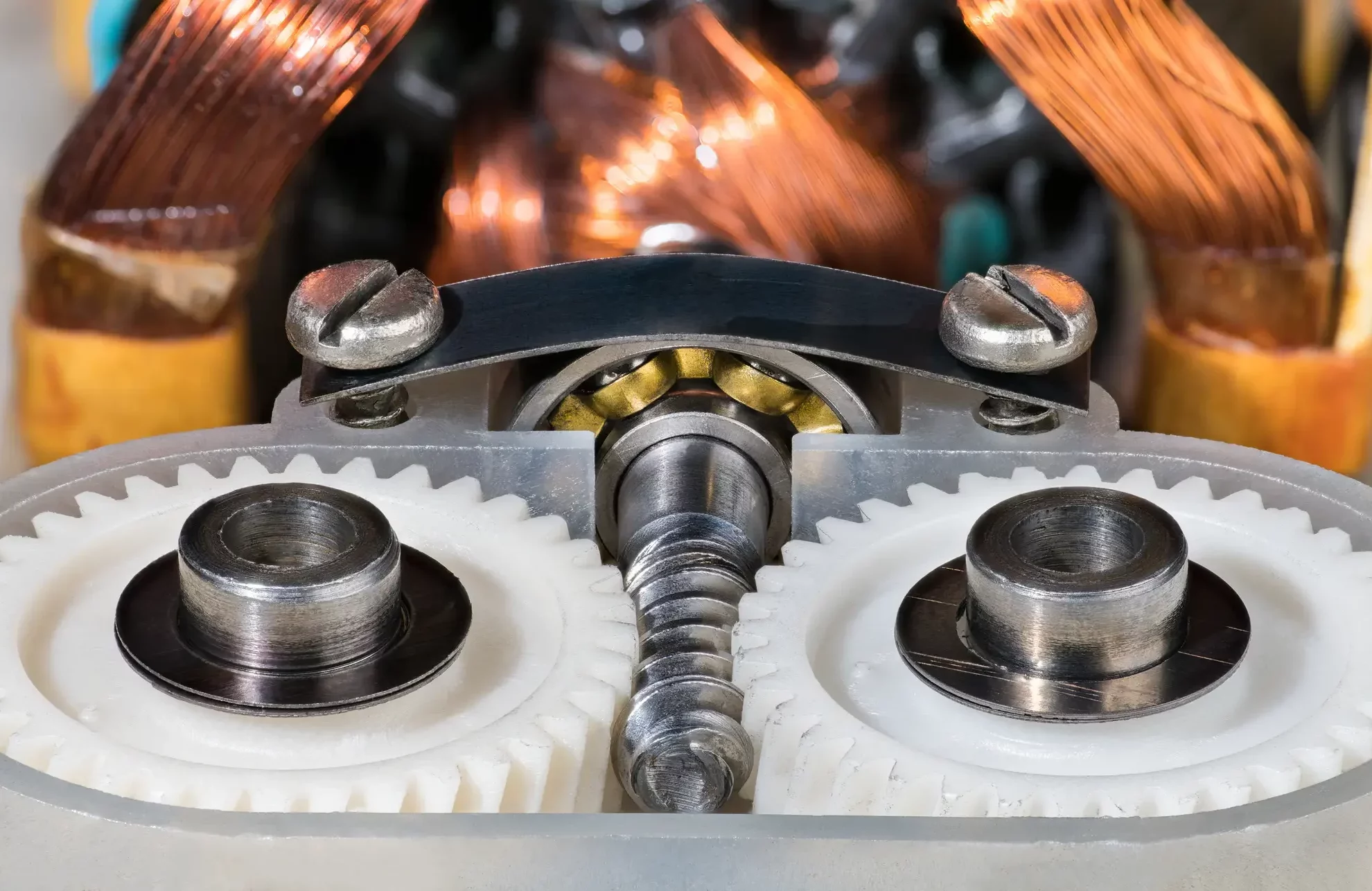

Automotive industry:

Integration of plastic and metal components for lightweight and aerodynamically optimized parts. The substitution of metal with plastic will play an even greater role in terms of energy efficiency in the future. By replacing metal parts with materials like PEEK plastic, weight can be reduced while maintaining chemical resistance and excellent mechanical properties.

Electronics:

Robust and aesthetically pleasing components, such as enclosures and coverings, that provide insulating protection against moisture and dust.

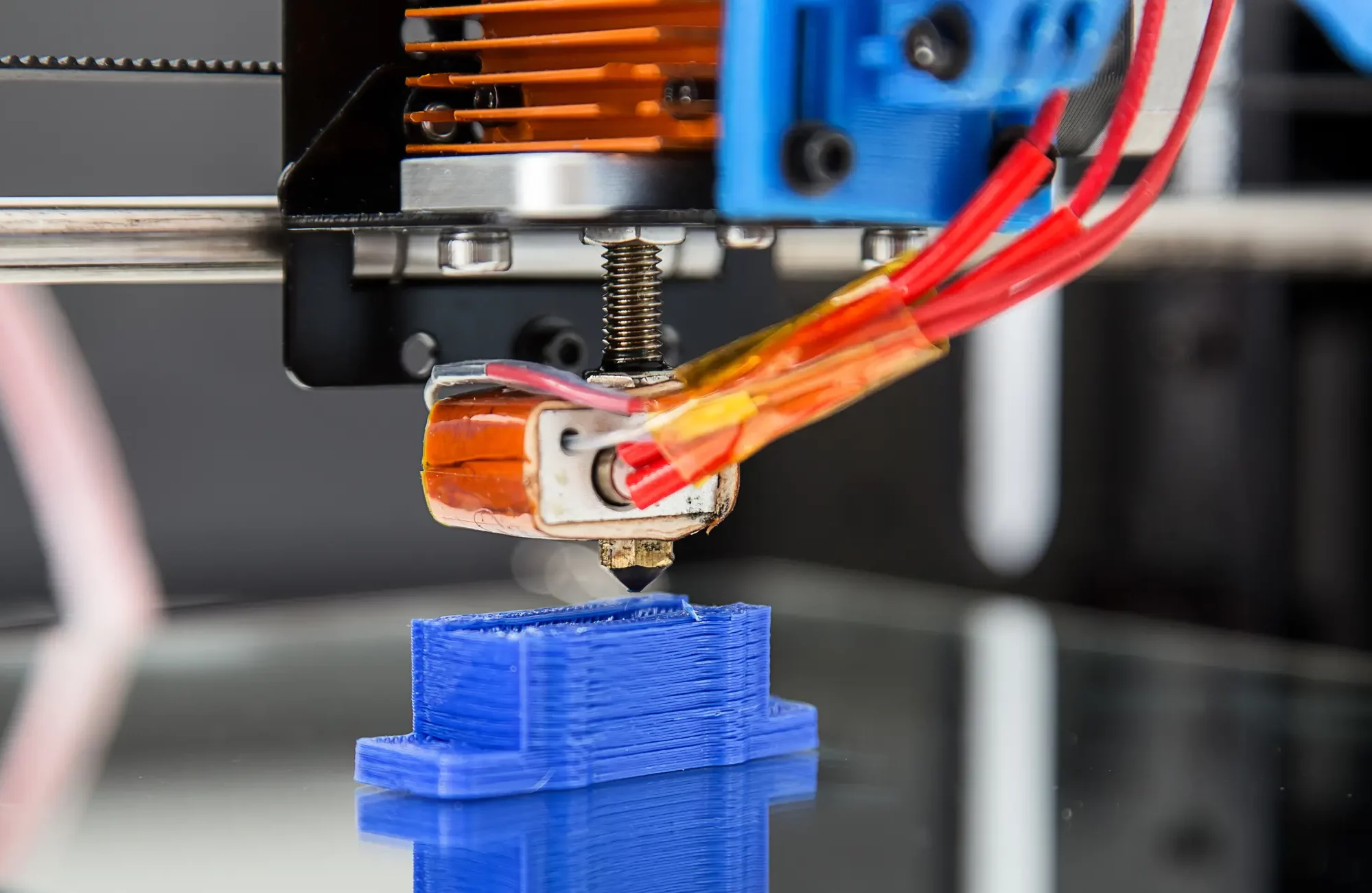

Prototype building 3D printer:

Additive manufacturing and 3D printing prototyping allow us to create prototypes for comprehensive design and handling tests.

With us, you receive a high-quality solution tailored to your individual needs.

We process the following high-performance polymers and high-tech fluoropolymers, among others:

-

VESPEL® - Polyimid

-

PA - Polyamid

-

POM - Polyoxymethylen

-

PCTFE - Polychlortrifluorethylen

-

PEEK - Polyetheretherketon

-

PET - Polyethylenterephthalat

-

PBT-GF30 - Polybutylenterephthalat glass fiber reinforced

-

PPSU - Polyphenylsulfon

-

ECTFE - Ethylenchlorotrifluorethylen

-

PP - Polypropylen

-

PE - Polyethylen

-

PTFE - Polytetrafluorethylen

-

PVDF - Polyvinylidenfluorid

-

PC - Polycarbonat

-

PVC - Polyvinylchlorid

-

PE-UHM - Polyethylen ultra-high molecular

-

PPS - Polyphenylensulfid

-

PMMA - Polymethylmethacrylat